|

TongShuo Medical Appliance Co., Ltd.

|

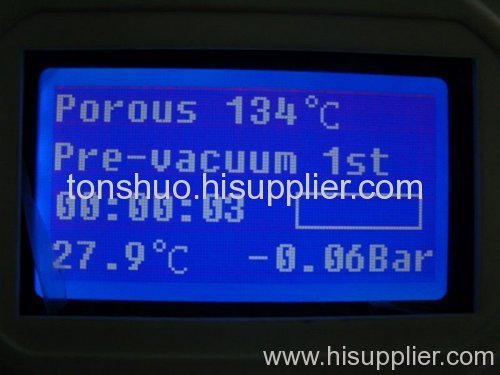

European B vacuum autoclaves

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.LCD display show the detail clearly

2.steam compensation technique

3.use printer inside

4.European B standard

5.CE,ISO9001/13485,EN13060 approve

1.LCD display show the detail clearly

2.steam compensation technique

3.use printer inside

4.European B standard

5.CE,ISO9001/13485,EN13060 approved

Specification:

| Model | T& S14B | T& S17B | T& S 23B |

| ChamberDimensions(mm)(Φ × D) | 250× 270 | 250× 380 | 250× 500 |

| ChamberCapacity(liter) | 14L | 17L | 23L |

| OverallSize(cm)(L× W× H) | 48× 48× 52 | 48× 56× 42 | 48× 67× 42 |

| Heater | 1600W | 1800W | 2000W |

| Net Weight(KGS) | 37 | 46.5 | 56 |

| Gross Weight(KGS) | 45 | 55 | 65 |

| Packing Size(cm) | 68× 60× 50 | 73× 60× 50 | 87× 60× 50 |

| Minimum DeskSize(cm) | 48× 35 | 48× 40 | 48× 50 |

| Power Supply | 220± 10%, 50/60HZ, 10A | ||

| Sterilize Temperature | 121/134 | ||

| Sterilize Time | Please refer to different programs. | ||

| Dry Procedure | Vacuum drying | ||

| Sterilizer Construction | Stainless steel SUS#304 | ||

| Water tank | internal | ||

| Stainless steel instrumentcontainer: | 3trays | ||

1. According with EN 13060

2. Pass CE, ISO9001, ISO13485

3. LCD display easy for operation

4. Steam compensation techniques

5.use inner printers

6. LCD display, 8 programs Automaticly feeding water and draining water system easy to operate.

7. Full-Automatical operation, check and monitor by computer

8. Printer inside, note the sterilization process in details

9. Automatic and safety door lock system

10. Have an enaluation system of sterilization process

11. According to Europer B standard, with 3 times pre-vacuum

12. The water setting is full-automatic

13. Can show the reason of failure on LCD, do not need to check recording to code menu

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!